Simulation for logistics decision-making

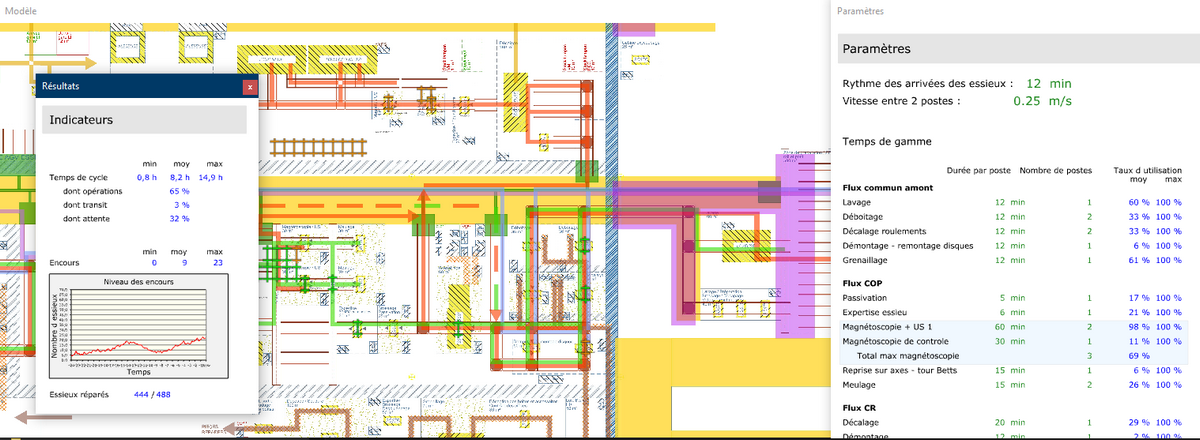

Simulation aims to model the dynamics of a process or system in its current configuration and according to several evolution scenarios. It is both a predictive method and an educational tool, enabling us to project the evolution of a network, a warehouse or a workshop through its digital twin, and offers 3D or 2D visualization on a plan, as required. Thanks to experimental designs, simulation can be used to calculate key indicators such as load and utilization rates, cycle times, WIP, stock-outs and waiting times, and to visualize their effects and understand their causes. It is a powerful tool for building scenarios and guiding the choice of the best-performing and most robust scenario, i.e. the one that performs best in the face of hazards likely to occur (variations in demand, breakdowns or supply disruptions).

We operate in various sectors

Large groups, institutions, SMEs ; we have the resources to support companies of all sizes and in all circumstances (from long-term vision to crisis support)

Supply chain is becoming an integral part of industrial sites. Managing site supplies means working more closely with suppliers, and integrating factory workflows into the supply chain.

Our work focuses on issues relating to the organization and management of physical flows, as well as on forward-looking studies linked to territories. Our areas of expertise include urban logistics, modal shift and carbon footprint.